A contactors lra rating may be: – With a contactor’s LRA rating may be: at the forefront, this paragraph opens a window to an amazing start and intrigue, inviting readers to embark on a storytelling journey filled with unexpected twists and insights.

A contactor’s LRA (Locked-Rotor Amps) rating is a crucial factor to consider when selecting a contactor for an application. This rating indicates the maximum current the contactor can withstand when the motor it controls is starting. Understanding the factors that affect LRA ratings and how to match them to load requirements is essential for ensuring reliable and efficient contactor operation.

LRA Ratings: A Contactors Lra Rating May Be:

LRA ratings are a crucial aspect of contactor selection, as they determine the contactor’s ability to handle high inrush currents. Inrush currents are momentary surges of current that occur when a contactor is first energized. These currents can be several times higher than the normal operating current, and if the contactor is not properly rated, it can lead to premature failure.There

are two main types of LRA ratings for contactors: locked-rotor current (LRC) and inrush current (IRC). LRC is the current that flows through the contactor when the motor it is controlling is locked in the rotor position. IRC is the current that flows through the contactor when the motor it is controlling is starting up.The

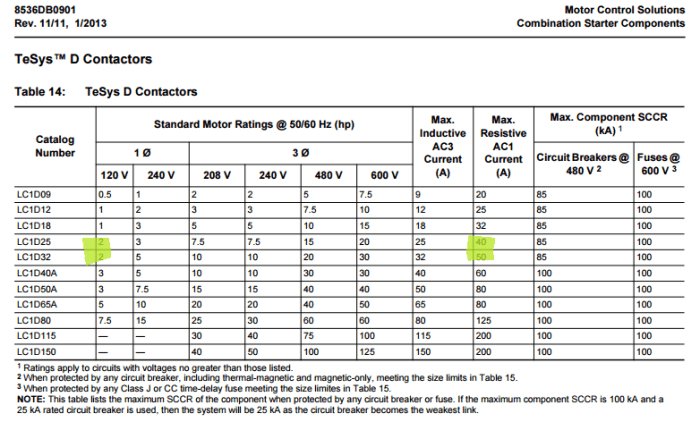

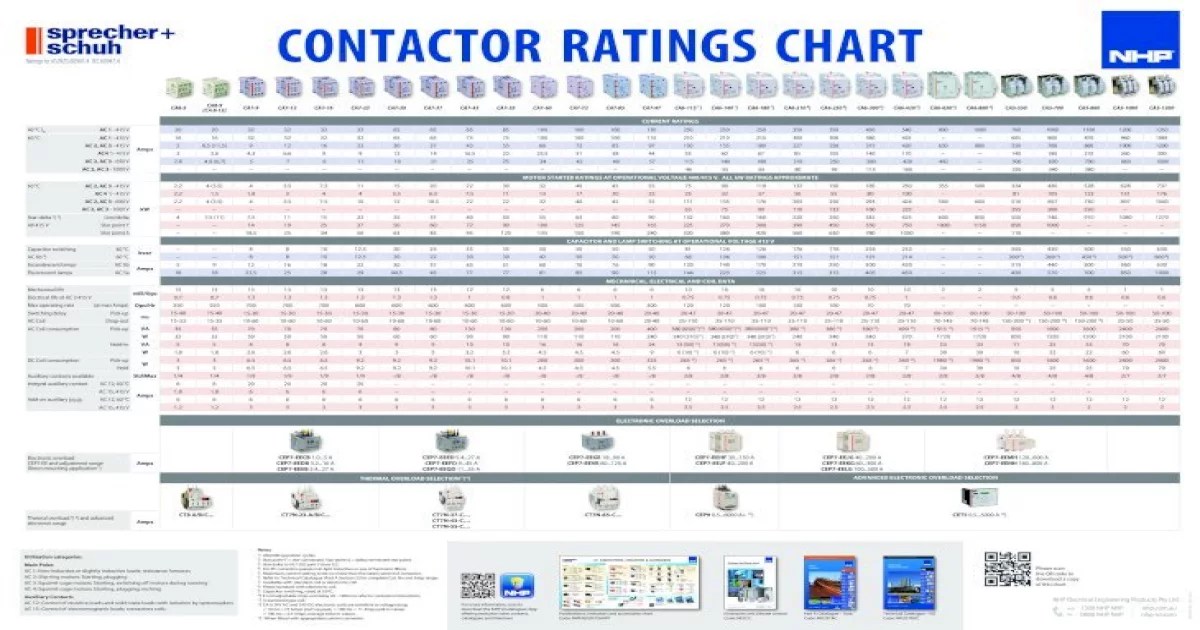

following table provides a summary of the different types of LRA ratings for contactors, along with their definitions and typical applications:

| Rating Type | Definition | Typical Applications |

|---|---|---|

| Locked-rotor current (LRC) | The current that flows through the contactor when the motor it is controlling is locked in the rotor position. | Motors with high starting torque requirements, such as compressors and pumps |

| Inrush current (IRC) | The current that flows through the contactor when the motor it is controlling is starting up. | Motors with low starting torque requirements, such as fans and blowers |

Factors Affecting LRA Ratings

The LRA rating of a contactor is influenced by several factors, including the voltage, current, and contact design. These factors determine the amount of current that the contactor can handle without overheating or causing damage.

Voltage

The voltage of the circuit in which the contactor is used affects its LRA rating. Higher voltages require contactors with higher LRA ratings to handle the increased current flow. This is because higher voltages create a greater potential difference across the contacts, which can lead to arcing and overheating if the contactor is not rated for the appropriate voltage.

Current

The current flowing through the contactor also affects its LRA rating. Higher currents require contactors with higher LRA ratings to prevent overheating and damage. This is because higher currents generate more heat, which can cause the contacts to melt or weld together if the contactor is not rated for the appropriate current.

Contact Design, A contactors lra rating may be:

The design of the contactor’s contacts also affects its LRA rating. Contacts that are made of different materials or have different shapes can have different LRA ratings. For example, silver contacts have a higher LRA rating than copper contacts because silver is a better conductor of electricity and generates less heat.

Additionally, contacts that are designed to make multiple breaks can have a higher LRA rating than contacts that are designed to make only a single break.

LRA Ratings and Contactor Selection

Understanding LRA ratings is crucial when selecting contactors. These ratings indicate the ability of a contactor to withstand the high inrush currents that occur when inductive loads are energized. Matching LRA ratings to load requirements ensures reliable operation and prevents premature contactor failure.

To determine the appropriate LRA rating for a contactor, consider the following guidelines:

- Identify the load’s LRA, typically specified by the load manufacturer.

- Select a contactor with an LRA rating that exceeds the load’s LRA by a safety margin of at least 20%.

- Consider the operating conditions, such as temperature and altitude, which can affect LRA ratings.

Potential Consequences of Using Contactors with Inadequate LRA Ratings

- Premature contactor failure due to excessive current draw.

- Contact welding, resulting in the contactor remaining closed even when de-energized.

- Arcing and damage to the contactor’s contacts.

- Increased risk of electrical fires and equipment damage.

- System downtime and reduced productivity.

Applications and Examples

LRA ratings play a crucial role in determining the performance and longevity of contactors in various applications. Understanding how LRA ratings impact contactor performance in real-world scenarios is essential for proper contactor selection and application.

Industrial Machinery

Industrial machinery often involves high-power motors with high inrush currents. Contactors with appropriate LRA ratings are necessary to handle these high inrush currents without welding or premature failure. For instance, a conveyor system with a 200 HP motor may require a contactor with an LRA rating of at least 3,000 A to withstand the high inrush current during motor startup.

A contactor’s LRA rating may be a crucial factor to consider, especially when the contactor is used in applications with high inrush currents. On a different note, have you ever wondered what Dill dares Jem to do? Discover the daring challenge that tests the limits of Jem’s courage.

Returning to our topic, it’s important to ensure that the contactor’s LRA rating is adequate to handle the expected inrush current to avoid potential damage or malfunction.

HVAC Systems

HVAC systems frequently employ contactors to control the operation of compressors and fans. The LRA rating of the contactor must be sufficient to handle the high inrush current of the compressor or fan motor. In a commercial HVAC system, a 50-ton compressor may require a contactor with an LRA rating of 1,500 A or higher to ensure reliable operation.

Lighting Control

Contactors are used in lighting control systems to switch high-wattage lighting loads. The LRA rating of the contactor should be adequate to handle the inrush current of the lighting load. For example, a contactor controlling a 100 kW lighting load may require an LRA rating of 1,000 A or higher to prevent contact welding and ensure proper load switching.

LRA Ratings in Electrical Design

LRA ratings play a crucial role in electrical design calculations, ensuring that contactors can withstand the high inrush currents that occur when inductive loads are energized. Incorporating LRA ratings into design equations helps prevent contactor failures and ensures system reliability.

Step-by-Step Process

To incorporate LRA ratings into design equations, follow these steps:

- Determine the inductive load’s characteristics, including its inductance (L) and resistance (R).

- Calculate the LRA using the formula: LRA = V / (√(R^2 + (2πfL)^2)), where V is the voltage, f is the frequency, and L is the inductance.

- Select a contactor with an LRA rating that is equal to or greater than the calculated LRA.

Industry Standards

According to the National Electrical Code (NEC), contactors used for inductive loads must have an LRA rating that is at least 1.5 times the full-load current of the load.

Answers to Common Questions

What is the difference between LRA and FLA ratings for contactors?

LRA (Locked-Rotor Amps) rating indicates the maximum current a contactor can withstand when the motor it controls is starting, while FLA (Full-Load Amps) rating indicates the maximum current the contactor can carry continuously.

How do I determine the LRA rating required for a contactor?

The LRA rating should be at least equal to the starting current of the motor being controlled. Refer to the motor manufacturer’s specifications or use an LRA calculator to determine the required rating.

What are the consequences of using a contactor with an inadequate LRA rating?

Using a contactor with an inadequate LRA rating can lead to premature contactor failure, motor damage, and potential safety hazards due to overheating or arcing.